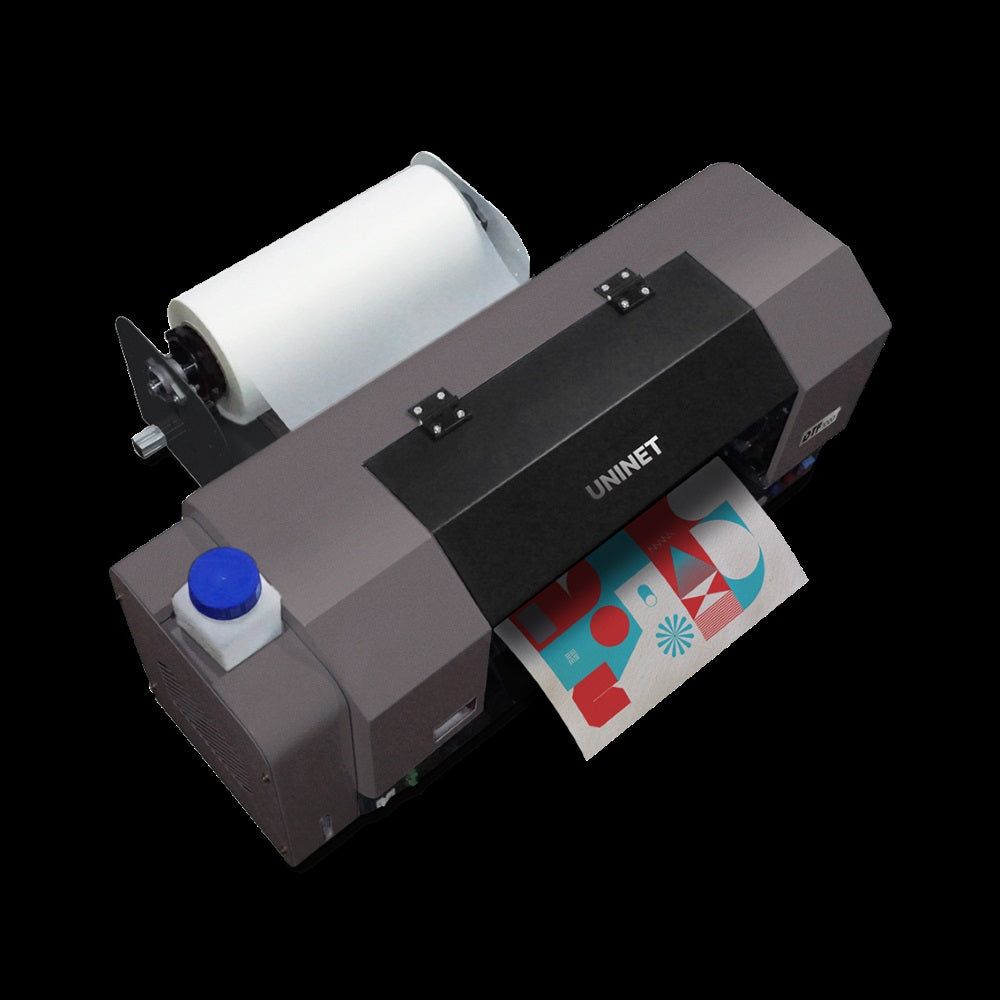

Uninet 1000 Roll Fed DTF Printer (Includes Training, Starter Package, 1Yr Warranty)

Most Relevant Info at One Glance

- High Resolution Printing: 1440dpi

- Print Speed: Up to 13 square ft/hr

- Ink System: 6 Channel (CMYK + White) with self circulation; no need to shake the ink

- Compact and lightweight Design: 27.5" × 23.6" × 15.7" | Weight: 48 lbs

- Warranty: 12 months (extended warranty available)

- Includes: DTF inks (500ml), 328 ft transfer paper, adhesive powder (1.75lb) ProRIP software, and training material & support

Features

The UNINET™ DTF 1000 printing system is an affordable and reliable solution built on the popular Epson engine, professionally modified and enhanced by UNINET™. This bi-directional roll feeder system produces durable and intense color prints, works on multiple fabric types including cotton, poly, and blends, and is compatible with both light and dark textiles. Ideal for batch printing operations, the DTF 1000 offers incredible overall value with advanced features including a white ink circulation system, vacuum-enhanced printing area, and comprehensive training and support.

- Built on the popular and reliable Epson engine, professionally modified and enhanced by UNINET™

- Produces durable and intense color prints with 1440 dpi resolution

- Works for multiple fabric types (cotton, poly, blends and more)

- Compatible with both light and dark textiles

- Bi-directional roll feeder system - accepts rolls up to 13" wide

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- Print speed: up to 13 square ft / hr

- WICS (White Ink Circulation System) for consistent white ink performance

- 6 Channel Technology (for White and CMYK)

- XL White Ink Tank and Advanced Continuous Feed System

- Humidity Sensor for optimal printing conditions

- RIP and Roller Software Included

- Advanced Roller system for easy and fast feed controls

- DTF specialized Damper system for improved pressurized delivery of ink

- Efficient and simple flush system with flush cartridges or bottles

- Efficiently designed exterior shell and frame structure

- Conveniently located front control designs

- Compact dimensions: 27.5" x 23.6" x 15.7" / 70cm x 60cm x 40cm

- Lightweight: 48lbs / 21.7kg

- 12 Month Warranty with option for 1 year extended warranty

- World Class Service and Support direct from UNINET™

IMPORTANT: DTF systems require constant use and maintenance. This is not for the occasional user! ONCE INK IS INSTALLED, THE PRINTER MUST BE USED OR MAINTAINED DAILY!

Included Items

- UNINET™ DTF 1000 Printing System

- DTF Inks (CMYKW) – 500ml bottles

- 328 ft roll DTF Transfer paper

- DTF Adhesive Powder (aka Transfer Powder) – 1.75lb bottle

- DTF Starter Bundle (Hygrometer, Maintenance Solutions and Accessories)

- UNINET™ DTF ProRIP Software

- Training via the DTF Master Class Video

- Remote 30 minute Q&A session with a live technician

- World Class Service and Support direct from UNINET™

Specifications

| Specification | Details |

|---|---|

| Model | UNINET™ DTF 1000 |

| Engine | Epson (professionally modified and enhanced by UNINET™) |

| Print Resolution | 1440 dpi |

| Print Speed | Up to 13 square ft / hr |

| Maximum Roll Width | 13 inches |

| Ink Technology | 6 Channel Technology (White and CMYK) |

| White Ink System | WICS (White Ink Circulation System) with XL White Ink Tank and Advanced Continuous Feed System |

| Printing Area Enhancement | Vacuum-enhanced for better ink adhesion and film buckling prevention |

| Damper System | DTF specialized for improved pressurized delivery of ink |

| Flush System | Efficient and simple with flush cartridges or bottles |

| Additional Features | Humidity Sensor, Advanced Roller system, Bi-directional roll feeder |

| Dimensions | 27.5" x 23.6" x 15.7" (70cm x 60cm x 40cm) |

| Weight | 48 lbs (21.7 kg) |

| Software Included | UNINET™ DTF ProRIP Software, RIP and Roller Software |

| Fabric Compatibility | Cotton, polyester, blends, and more (light and dark textiles) |

| Warranty | 12 Month Warranty (1 year extended warranty available) |

Important Safety and Usage Information

WARNING: WORK IN A WELL VENTILATED AREA and use protective equipment when working with DTF products and processes. UNINET™ highly recommends the use of a fume extractor to handle the fumes caused by TPU adhesive powder curing. Bodily protection, including the use of PPE equipment such as a full body covering, a respirator / N95 mask, goggles and gloves are recommended to protect against TPU adhesive powder (prior to curing) that may become airborne due to handling. Inhalation of TPU adhesive powder or fumes may be hazardous to your health. The use of DTF equipment, chemicals, powders, inks and all accessories are at the sole risk of the user. DTF equipment is intended for use in a commercial environment. UNINET™ does not recommend the use of DTF equipment in a residential, or in-home setting. DTF inks and film require a good humidity environment - over 50% humidity is highly recommended to minimize risk of ink clogs and film buckling.